As the facmouse supplier in the clamp real, we are also the supplier for the famous brand customers. These are some of the customers who choose us as a reliable clamp product supplier.

We have 3 factories, including clamp production, mold production, Vietnam factory.

Tianyuan Clamp No.1 Factory

OET clamp (ear type clamp) full series manufacturing center, with a production scale of 150 people. Founded in 2010, it has a history of 15 years and serves more than 3ooo auto parts enterprises. The single ear clamp has achieved first place in domestic production!

Tianyuan Clamp No.2 Factory

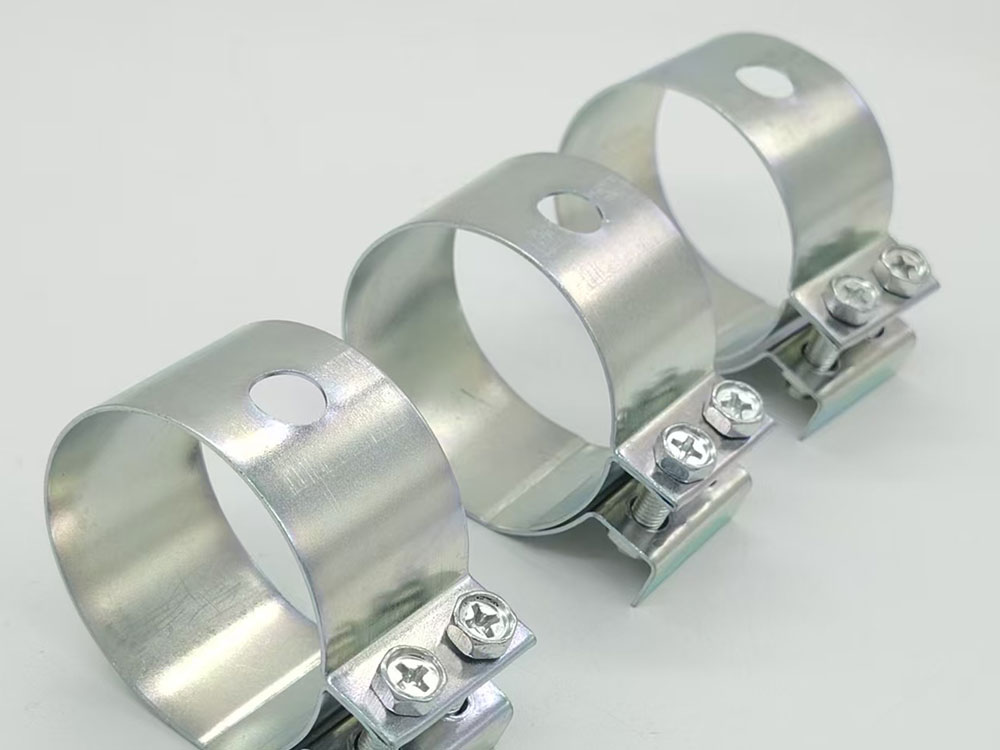

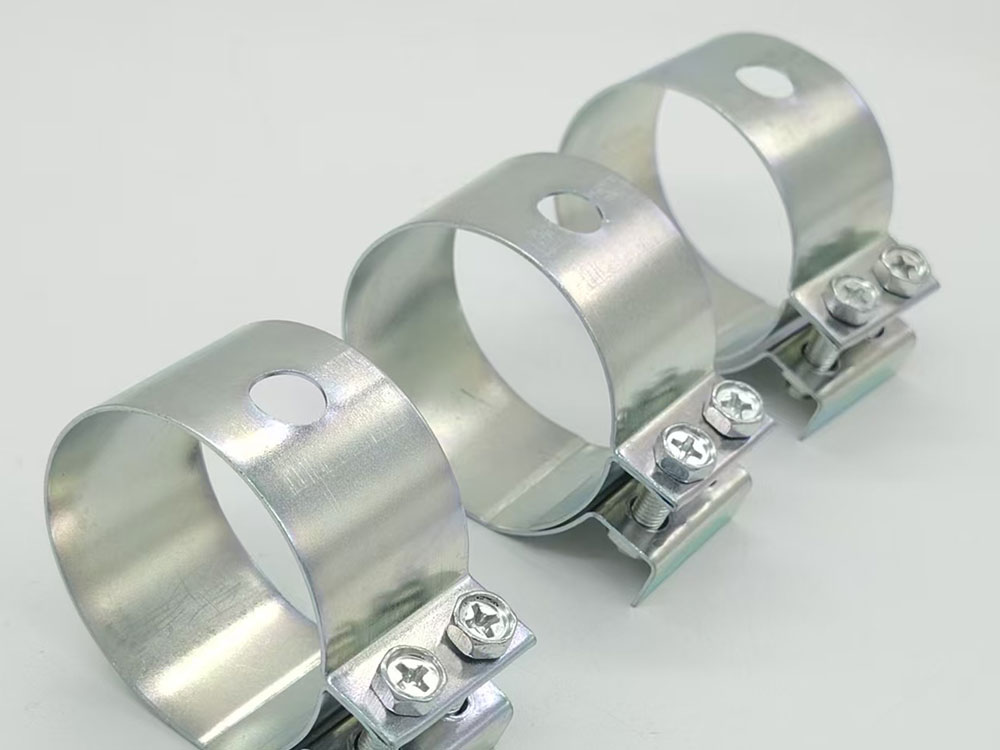

Tianma Clamp Center factory. The fast delivery system for high-end customized clamps and the manufacturing center for worm-type clamps have a capacity of 100 people, with plans to achieve the first place in domestic worm-type clamps within 3 years.

Tianyuan Automation No.4 Factory

Design, manufacture, and delivery of the clamp automation production equipment and customer on-site installation automation equipment for 20 people.

In 2005, Yamaha Japan found a clamp enthusiast and asked us to develop a single-ear infinite clamp for use in Yamaha’s suspension engines (a type of marine engine). At that time, the domestic market was relatively blank, with only some low-end product industries that could not meet the needs of Japanese customers. At the same time, foreign brand manufacturers had just entered China, and the long delivery time made customers very anxious. But the clamp maniac has never had contact with it. I searched for information everywhere and contacted manufacturers in Taiwan to develop this product. With only a little money, the clamp enthusiast bought Taiwanese equipment in a very dilapidated house for research and development. After three months of hard work and hard work, the product was finally developed and delivered to Yamaha in Japan. This is the source of our first clamp.

We have strong automation development capabilities and the ability to develop our own automation equipment. We can achieve the best production efficiency through automated production according to the production requirements of different products of customers, while meeting the quality requirements and achieving the best cost.

We have strong automation development capabilities and the ability to develop our own automation equipment. We can achieve the best production efficiency through automated production according to the production requirements of different products of customers, while meeting the quality requirements and achieving the best cost.

The traceability capability of individual products and the online production progress query system for customized parts are unique features of our automation equipment. They can spray QR codes on products, achieve single product scanning traceability, and query product batch numbers and production dates. They are suitable for high-end applications. At the same time, our company also supports online inquiry of customized products. The digital factory allows you to visually see the entire process from placing an order to shipping, making your purchases more reassuring.

We can customize the tools you need for installing clamps and products. We can develop installation tools specifically for your product to improve installation efficiency. Currently, widely used tools include the rated torque installation tool for worm type throat clamps and the single ear clamp installation tool. Other tools can be developed according to your needs, including electric, pneumatic, and manual tools, greatly increasing your installation efficiency.

Our mold center allows us to quickly customize products for Tianyuan Mold Production Factory. We can design and develop products and molds, and can develop and produce molds for different application scenarios of our customers. We can produce molds ourselves and can quickly respond to customers’ customized clamp development needs.

We have a large number of patents for the clamp products as the professional Group manufacturer of clamp products,

We are a professional Group manufacturer of clamp products, and the quality is the most important thing we are concerned about. We have a series of testing equipment and processes to ensure our clamp product is of good quality for your product

The clamp clamping force tester can test the clamping force of the clamp from eight testing points in different directions.

For the testing of clamp application scenarios, we have the ability to simulate the actual production site of customers for clamp assembly testing, in order to maximize the solution to customer installation site problems.

About TFurther, news, technology and knowledge

The following terms and models apply to this standard:

Single-Ear Infinite Clamp: Refers to a clamp with no protrusions or gaps on the inner ring. The infinite design ensures uniform force distribution on the pipe surface, providing 360° sealing.

The following terms and models apply to this standard:

Single-Ear Infinite Clamp: Refers to a clamp with no protrusions or gaps on the inner ring. The infinite design ensures uniform force distribution on the pipe surface, providing 360° sealing.

The following terms and models apply to this standard:

Single-Ear Infinite Clamp: Refers to a clamp with no protrusions or gaps on the inner ring. The infinite design ensures uniform force distribution on the pipe surface, providing 360° sealing.

Stop thinking more, just fill out the blank below and send us an inquiry, and you will have a professional team from our products contact you to answer any questions and provide pricing.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.